CONTACT US

Mining Equipment Screen

Support to provide drawings or samples processing.

- Product Description

-

Our Linear Dewatering Screen is engineered for high-efficiency solid-liquid separation, dehydration, and classification of

fine-grained materials in industries such as mining, construction, and environmental management. Featuring advanced vibration

technology and robust construction, it delivers superior dewatering performance while minimizing operational costs.

Core Features & Benefits

1. Optimized Dewatering Efficiency

* Utilizes dual-motor synchronized vibration technology to generate intense linear motion (50Hz frequency, 8–10×

gravitational acceleration), ensuring rapid water removal and precise screening of particles ranging from 0.074–1mm.

* Negative-angle screen installation enhances, reducing moisture content in outputs like sand and tailings to below 15%

2. Durable & Maintenance-Friendly Design

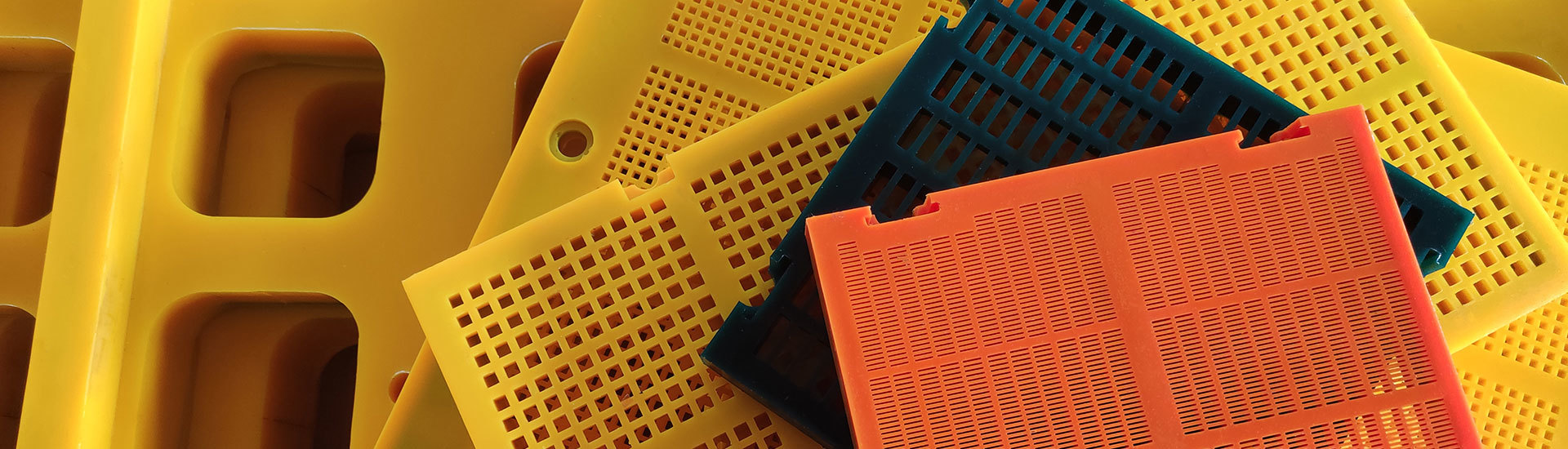

* Polyurethane screens: High wear resistance, anti-clogging, and extended service life compared to traditional materials like stainless steel or carbon steel.

* Reinforced frame: Constructed with HUCK rivet-assembled side panels and polyurethane-coated beams to prevent deformation, corrosion, and stress cracks.

* Modular components: Quick-replacement screen hooks and accessible vibrators simplify maintenance.

3. Customizable Configurations

* Adjustable amplitude (0–2mm), screen aperture (0.25–50mm), and multi-layer setups to accommodate diverse materials (e.g.,sand, coal, ores).

* Optional stainless steel composite screens or welded slit panels for tailored applications.

4. Energy-Saving Performance

* Low-power motors (2×4kW to 2×30kW) and optimized vibration systems achieve up to 500 t/h with minimal energy consumption.

* Frequency converters allow real-time adjustment of vibration intensity for peak efficiency.

Applications

* Sand Processing: Reduces moisture in washed sand to <0.7% for construction-grade materials.

* Mining & Tailings Management: Efficient of gold, copper, and iron tailings for eco-friendly storage and transport.

* Coal Washing: Dewaters coal slurry to improve fuel quality and reduce disposal costs.

* Environmental Remediation: Treats industrial sludge and wastewater for sustainable resource recovery

Factory Video

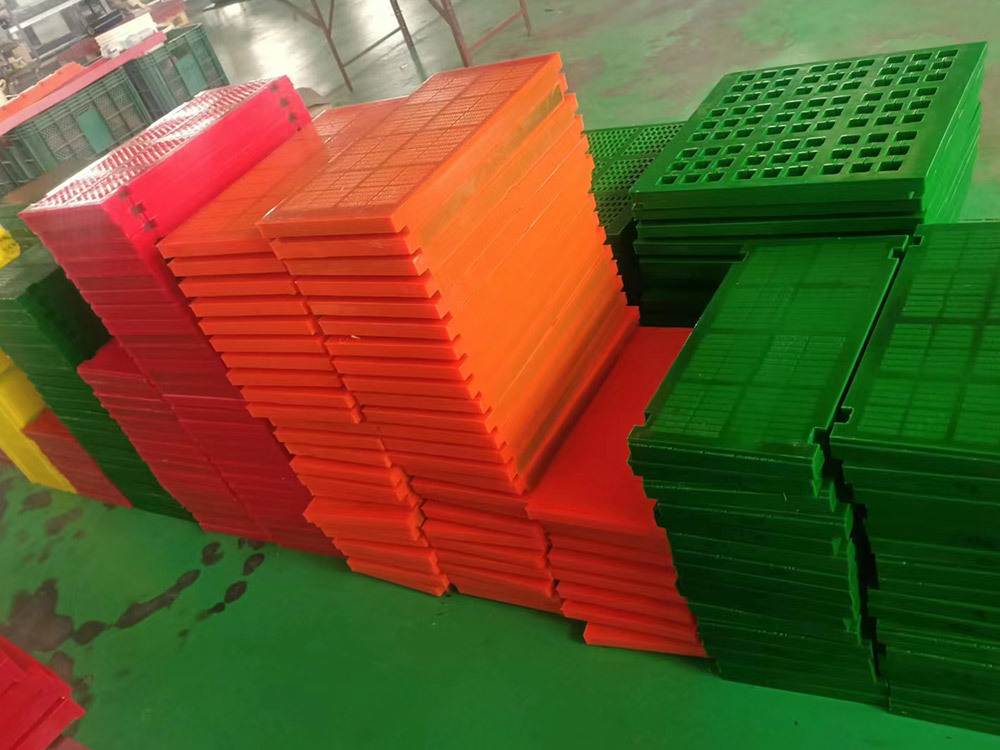

The company covers an area of 15,000 square meters, has a standardized plant of 6,600 square meters, has a complete set of polyurethane product production equipment and diversified machining production capacity. The company takes it as its mission to meet customer requirements and has been committed to the research and development and production of high-performance polyurethane rubber products for many years.

Product Testing

Production & Delivery

Related Product

Send Inquiry

With professional production technology and high-quality products and services, Tonda has won the recognition and trust of our customers.

Get a Quote