CONTACT US

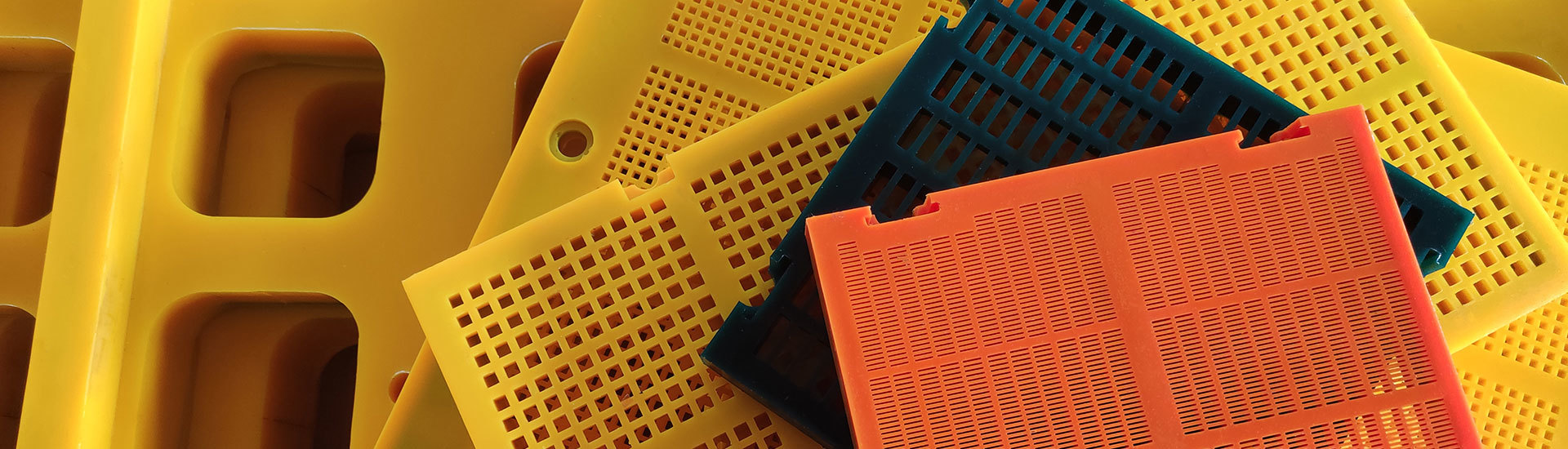

Dewatering Screen Panel

Support to provide drawings or samples processing.

- Product Description

-

Polyurethane screen plates are mainly used in coal mines, iron ore, copper mines, gold mines, tailings, concentrate dehydration, slime dehydration, chip removal, carbon slurry separation and other industries.After concentrating and dehydrating the tailings with low content of useful components in mineral processing, dry discharge can save the area of tailings, reduce tailings pollution, and eliminate safety hazards.

The dimensions can be customized according to the requirements of the screen machine and customers:305*305 305*610 500*500 600* 600, etc., with single ears, binaural ears, water retaining edges, etc.

Screen seam size can be customized:0.075、0.1、0.2、0.3、0.5、0.75、0.8 etc.

Installation methods that can be used: nails, bolts, rail seats, card slots, etc., The installation methods can be customized according to needs.

Features of Tonda polyurethane screen plate: The screen surface is flat, the screen holes are fine and transparent, the wear resistance is good, the screening efficiency is high, and the service life is long.

Product advantage:

1. Polyurethane dewatering screens have excellent wear resistance and their service life far exceeds that of traditional rubber screens and metal screens.

2. The polyurethane tailings dewatering screen is acid and alkali resistant, corrosion resistant, and can be used in various working conditions.

3. The screen seam accuracy of the polyurethane dewatering screen plate is high, and materials of different particle sizes can be graded to a large extent.

4. The coefficient of friction of the polyurethane dewatering screen is low, the screen is not sticky, and the screen is not easy to block holes.

5. The polyurethane dewatering screen itself is elastic, has a large processing capacity, sufficient dewatering, and high efficiency.

6. The installation method of polyurethane dewatering screen plate is simple and diverse, and it is easy to replace.

7. The polyurethane dewatering screen has low noise and reduces noise pollution.

8. Tonda specially made double-hardness MDI polyurethane screen plate, using imported three-component MDI polyurethane of different hardness.The design of upper softness and lower hardness makes the surface of the polyurethane screen highly resilient, effectively reducing the hole blocking rate, increasing the processing capacity, and the wear-resistant effect is better and the use time is longer.

Factory Video

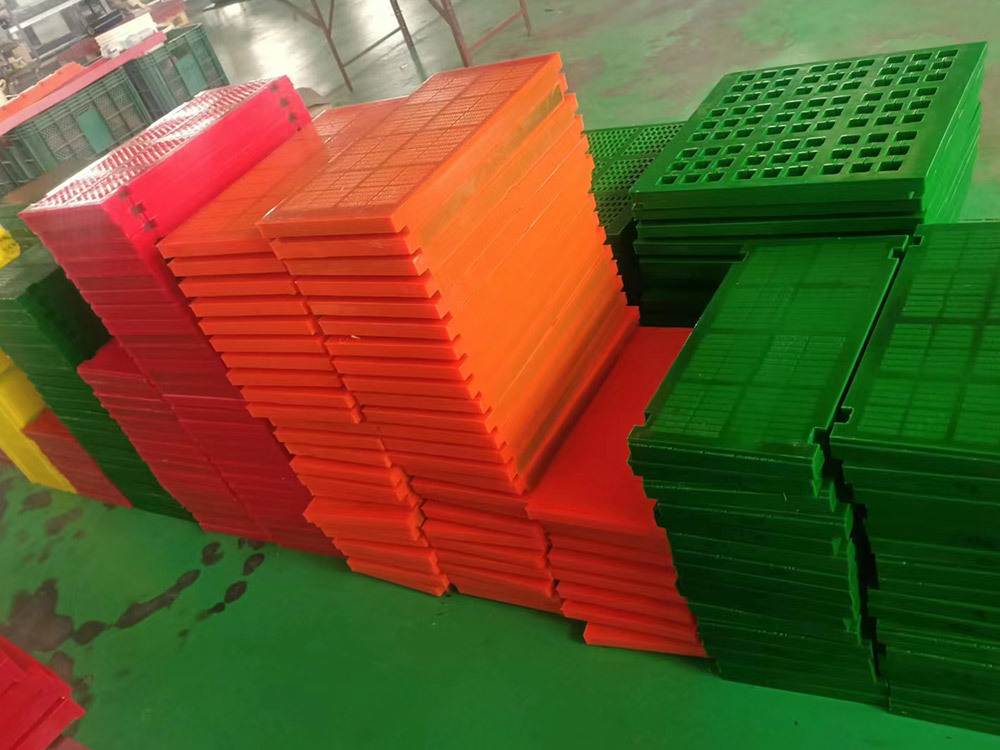

The company covers an area of 15,000 square meters, has a standardized plant of 6,600 square meters, has a complete set of polyurethane product production equipment and diversified machining production capacity. The company takes it as its mission to meet customer requirements and has been committed to the research and development and production of high-performance polyurethane rubber products for many years.

Product Testing

Production & Delivery

Related Product

Send Inquiry

With professional production technology and high-quality products and services, Tonda has won the recognition and trust of our customers.

Get a Quote