Uganda Linear Dewatering Vibrating Screen Machine

Support to provide drawings or samples processing.

Category:

UgandaVibrating Screen Machine

Product Description

Our Linear Dewatering Screen is engineered for high-efficiency solid-liquid separation, dehydration, and classification of

fine-grained materials in industries such as mining, construction, and environmental management. Featuring advanced vibration

technology and robust construction, it delivers superior dewatering performance while minimizing operational costs.

Core Features & Benefits

1. Optimized Dewatering Efficiency

* Utilizes dual-motor synchronized vibration technology to generate intense linear motion (50Hz frequency, 8–10×

gravitational acceleration), ensuring rapid water removal and precise screening of particles ranging from 0.074–1mm.

* Negative-angle screen installation enhances, reducing moisture content in outputs like sand and tailings to below 15%

2. Durable & Maintenance-Friendly Design

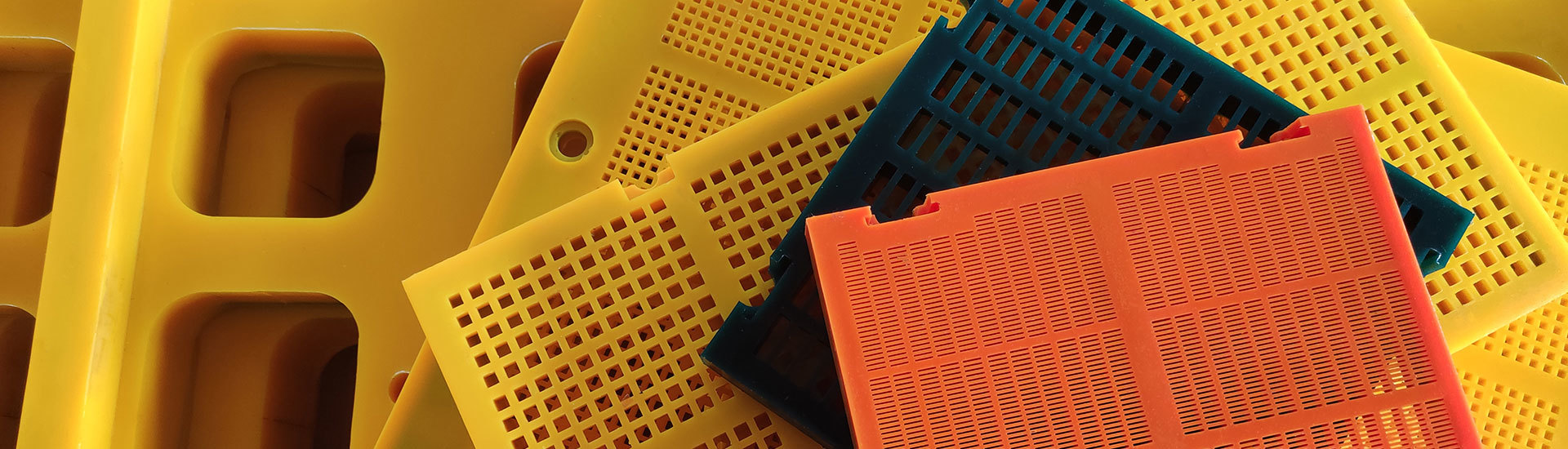

* Polyurethane screens: High wear resistance, anti-clogging, and extended service life compared to traditional materials like stainless steel or carbon steel.

* Reinforced frame: Constructed with HUCK rivet-assembled side panels and polyurethane-coated beams to prevent deformation, corrosion, and stress cracks.

* Modular components: Quick-replacement screen hooks and accessible vibrators simplify maintenance.

3. Customizable Configurations

* Adjustable amplitude (0–2mm), screen aperture (0.25–50mm), and multi-layer setups to accommodate diverse materials (e.g.,sand, coal, ores).

* Optional stainless steel composite screens or welded slit panels for tailored applications.

4. Energy-Saving Performance

* Low-power motors (2×4kW to 2×30kW) and optimized vibration systems achieve up to 500 t/h with minimal energy consumption.

* Frequency converters allow real-time adjustment of vibration intensity for peak efficiency.

Applications

* Sand Processing: Reduces moisture in washed sand to <0.7% for construction-grade materials.

* Mining & Tailings Management: Efficient of gold, copper, and iron tailings for eco-friendly storage and transport.

* Coal Washing: Dewaters coal slurry to improve fuel quality and reduce disposal costs.

* Environmental Remediation: Treats industrial sludge and wastewater for sustainable resource recovery

: next page

With professional production technology and high-quality products and services, Tonda has won the recognition and trust of our customers.

Get a Quote